Review – by Sean Fallesen of the International Plastic Modelers’ Society USA

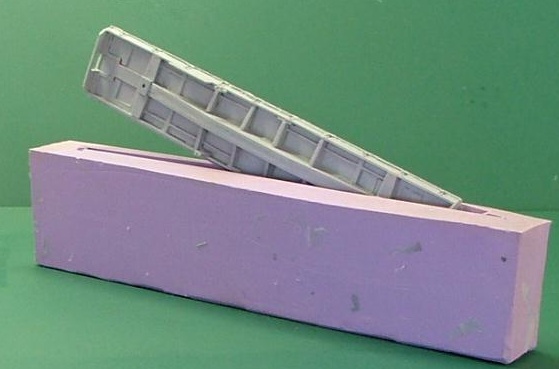

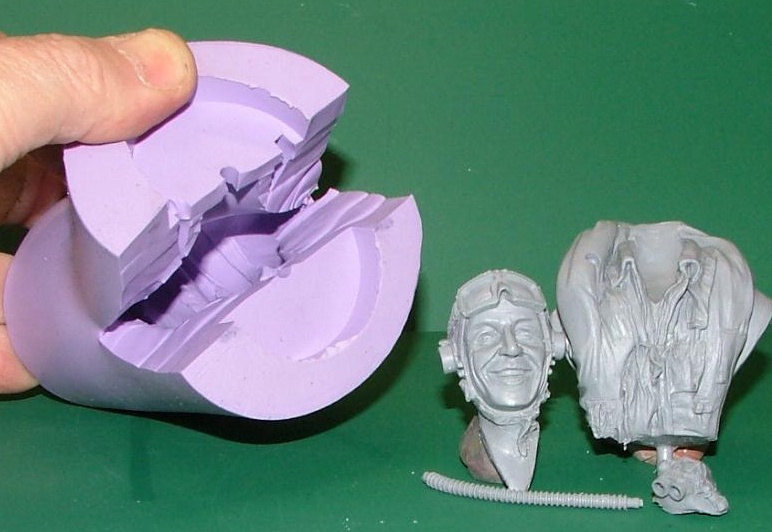

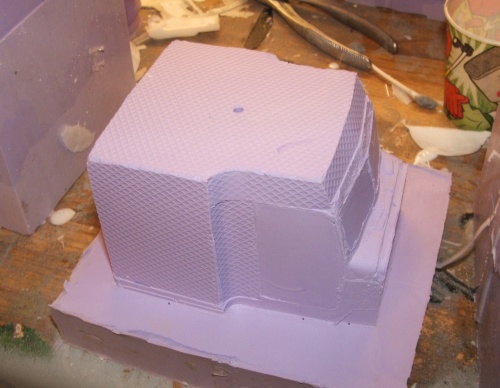

Since one needs a mold before one can properly assess casting resin, let’s start with the Hobby Silicone product. Using a 2 lb. tub of firm-formula silicone with the purple catalyst, I created several molds to test an assortment of shapes and sizes (My primary focus is 1:700 scale ships and 1:48 scale aircraft, to give some idea of the range). After giving them a full 24 hours to set, I removed the molds from the boxes, and the original parts from the molds. As advertised, the material is tough and tear-resistant, and a very sharp blade or is needed for cutting it. No surprises here, just a good mold-making compound. Even the batch I did not mix as thoroughly as I should have (as evidenced by the various shades of purple marbling) came out just fine.

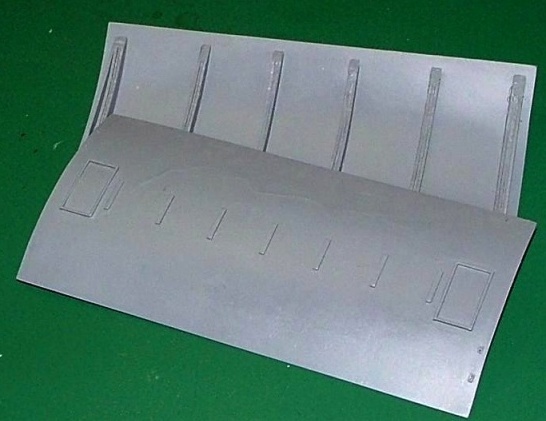

On to the casting resin. I used the MPK-90 formula (gel time of 120 seconds, vs. MPK-70 with 180 seconds) Components A and B smoky and clear, respectively, in color, and have a consistency close to that of cooking oil. Being nice and thin, they mix very easily. You need to be careful not to splash! After mixing, the resin remains clear and the consistency initially stays the same, making for a very quick, easy-flowing pour. It successfully flowed into long, narrow crevasses in the mold (i.e. splinter shields on 1:700 scale ship parts), though did not willingly work into very small impressions (i.e. 1:700 scale deck fittings) due to entrapped air. Some stretching of the mold would help a bit, though that does get messy sometimes. Even so, the performance is better than thicker casting materials I’ve used. The material is quite good; the rest is a matter of the caster’s techniques and skill level. There are a (very) few things for which I do favor a thicker material, but for the vast majority of casting jobs this is superior. The fact that the resin is clear when poured helps a lot in identifying obvious air pockets, and a quick probe with a toothpick can chase it right out.

As I was pouring into the several molds, I noticed the mix getting just a little thicker before it suddenly became a slush. When they say “gel time,” they mean gel time! The stuff coagulated very rapidly and clung to the side of the cup as I tried to pour. I set the cup down and it stayed right where it was, on a diagonal slope. At the same time, the mix began generating a lot of heat. So, enough of that – let it sit and cure.

By the way, about that toothpick probe thing: Once the resin hits that gel time, it will grab that toothpick, and pulling the toothpick out will take material with it. Thankfully the resin sticks to the side of the mold even better, so the air pocket you might accidentally create probably won’t breach the surface of the cast part. Still, be aware of that fact.

After about 15 minutes (around the time the cup had cooled off and the material inside felt decently hard and had turned a very opaque, very clean white), I set about pulling the parts out. I did not use any mold release compound (none was provided, and I was testing the product straight.). Not a problem, the resin did not stubbornly cling to the silicone. No significant shrinkage was observed even in the 10”-long ship hull I cast for just that purpose. (The small parts I usually cast being too small to use as a basis for observing shrinkage). I then subjected the parts to a series of tests for modeling suitability.

First, tests for gutting, sanding, and scratching.

One of my molds was just too tight, so I carefully cut down one side to remove the part. A very fine scratch was left in the surface of the part. However, upon dragging the tip of my X-acto over it the next morning, I saw no new scratch. Conclusion: be careful early on, but the parts will harden further, at which point they are very resistant to casual scratches.

Cutting properties are superb for resin. I was able to shave material off with no chipping. Use of clippers likewise produced no chipping, and cracks were less likely to form than in other resins I’ve used. A razor saw worked beautifully, and the material sands nicely.

I tested several types of paint on cleaned (wiped with paint thinner and dried off) and uncleaned surfaces. It turns out that performance was the same for both cases. Four tests were performed: Fingernail drag, knife scrape, Tamiya masking tape pull, and standard masking tape pull. The fingernail drag caused Tamiya paint to chip a little, the knife scrape a lot. Model Master enamel and Acryl and Gunze’s Mr. Surfacer were unaffected by the fingernail drag, and showed no stray chipping from the knife scrape. Tamiya tape did not remove any of the paints. Lastly, I tried the nasty old roll of hardware store masking tape that’s a bit stickier now that when it was new. Not a bit of paint pulled up with that one, either. Conclusion: Don’t scratch at Tamiya paint on a part made of this material. Aside from that, paint with no fear, and mask away with whatever you feel like using!

Squadron white putty does adhere to the material, and I had no problems with supergluing it. As expected, liquid model cement had no effect on it.

The fully cured material is quite stiff. A piece of cowling I cast was about 1/16” thick, and the resin duplicate was very difficult to bend. Stiff as it was, there was a decent amount of flex before it snapped. Stressing it close to that point and letting go resulted in the part maintaining its original shape, with no apparent permanent deformation. Very thin “parts” (i.e. hardened over pour puddles and drips) were different, showing an ability to deform almost to a complete fold before snapping. Conclusion: I have no fear of parts suddenly snapping in two from just an accidental squeeze. Some cold bending is possible on very thin parts (for example, 1:700 scale fighter aircraft wings, ship splinter shields), but from at 1/16” in thickness (and possibly even thinner than that) and up, cold bending doesn’t work. Fear not, though, because…

The old trick of heating parts in hot water then bending them works just fine here. Once the parts cool, they retain their new shape nicely.

In conclusion: I am very impressed with MPK’s product, particularly the casting resin. The modeling properties of this material are a refreshing change from the often-brittle, can’t-hold-their-paint resins I’ve frequently dealt with. And I mean actual kits, not self-casting projects. The Hobby Silicone is likewise impressive. I highly recommend this line and would like to thank Michael from MPK Enterprises and James Woody for the review sample.