Commonly used terms for Silicone Moldmaking:

Cure time

Even though a product can be demolded and feels cured, curing may continue for up to one week.

Demold time:

This is the soonest recommended time a cured part can be removed from the mold if the mold was cured at room temperature.

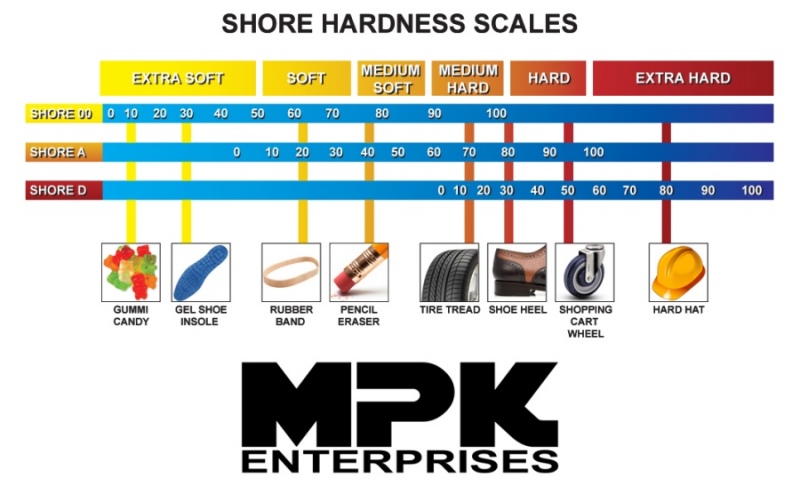

Hardness:

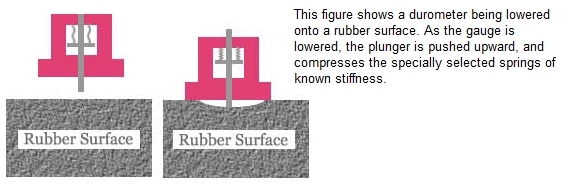

This property can be measured with an instrument called a Durometer gauge. The gauge has a needle which is pushed into the rubber. The farther the needle is able to penetrate into the rubber the lower the reading. (Softer the material ) The Shore A scale is used for reporting the durometer of most molding rubbers. The scale measurement is 0 – 100. The higher the reading , the harder the rubber. The durometer requirement of your silicone is dependent upon your application.

Is a result of a poisoning of the cure catalyst which stops the cross linking necessary for the silicone to properly cure. The result of inhibition is tackiness at the pattern interface or a total failure of the silicone to cure.

Addition Cure – Inhibition: materials known to inhibit cure are Sulfur-Containing clays, modeling clays, natural rubber such as latex and rubber gloves, masking tape, amine or sulfur containing materials, natural body oils, greasy fingers and condensation cure (catalyzed) silicones.

Condensation Cure – Inhibition: is not common. Some sulfur containing modeling clays can slow the cure of condensation RTVs. However , the condensation cure RTV will eventually cure when the clays are removed.

“ PLEASE NOTE ” INHIBITION CAN BE AVOIDED BY APPLYING A BARRIER COAT as described in the section of HOW TO MAKE A MOLD entitled ” Preparing the Mold “

Linear Shrinkage

Is the reduction in size which a user may experience during the life cycle of a silicone mold. The shrinkage is due to the release of a cure by-product in condensation cure systems, as well as “oils ” being drawn out of the mold by aggressive casting resins and other pourable casting systems.

Our ADDITION cured systems are known for Low Shrinkage.

Pour time, working time, pot life or gel time:

This is how much time the user will have before the material begins to gel. Your pour should be completed well before

the end of this time to insure good flow into the details of the mold and to allow any air bubbles to rise to the surface .

RTV: Room Temperature Vulcanization (room temperature cure).

Tear Strength: tear strength is a measurement of a rubbers ability to tear

Viscosity: Describes the consistency of a liquid. It is reported in centipoises (cps). The lower the reported number , the thinner the liquid. For example , water has a viscosity of 1 cps. while chocolate syrup will measure higher at approx. 1,000 cps. Catalyzed viscosities of silicone range between 7,500 and 105,000 cps.

There are four common types of molds (“Silicone Mold Types and How To Make A Silicone Mold“):

- Block mold: one piece with no negative drafts of undercuts. This is probably the easiest mold to produce. The original part should be placed in the box so the silicone is able to flow around it. If the part is simple, it can be placed in a plastic cup, a disposable plastic container or a wooden box (pine wood not recommended). If you choose a wooden box make sure to seal it properly if it appears to be porous.

- Block mold-multiple piece: This can be made exactly like a block mold and simply cut in half once it cures to remove the part. If you prefer not to cut the mold, partially fill the container and allow it to cure. Then apply a thin layer of release agent, and finish pouring the mold. When the second layer is cured, the mold should easily separate.

- Glove mold-brushed onto the pattern: This requires a thixotropic agent which allows the silicone to be brushed on an original piece without running off the surface. The thixotropic agent can be supplied in the catalyst or as a separate additive. This type of silicone is ideal for building restoration. The silicone can be bushed on an original piece of crown molding, allowed to cure and then be removed. The mold can then be taken back to the mold shop where parts can be cast to produce replications of the original molding. This type of molding is also becoming popular to cast rocks or stones to create molds of fake rocks, rock climbing walls, side walks and props for theme parks. Silicone Moldmaking Instructions!

- Cast Glove mold: This is made by creating a void around the original part in a consistent thickness. It is usually done by forming modeling clay around the pattern and then forming a hard shell around the clay. The shell can be made by using fiberglass, urethane or plaster. After the shell has cured, the clay is removed; creating a void which can be filled by silicone.